At Terzagen, we specialize in high-precision CNC machining, offering innovative solutions that meet the diverse needs of our clients across multiple industries. Our advanced technology, combined with skilled professionals, allows us to produce components that are both reliable and efficient. With a commitment to excellence, we ensure every CNC-machined part meets stringent quality standards, from intricate prototypes to large-scale production runs. Our focus on precision and adaptability enables us to deliver tailored solutions that enhance performance and drive client success.

At Terzagen, our CNC machining services are designed to deliver exceptional quality and precision for a variety of applications. Here’s a more detailed look at what we provide:

At Terzagen, we are dedicated to providing high-quality stamping solutions designed to meet the diverse needs of various industries. Our capabilities encompass a wide range of services, ensuring that we can address your specific requirements effectively. With advanced stamping technology and a focus on precision, we produce components that meet the highest standards in strength, accuracy, and finish. Our team works closely with clients to develop tailored solutions that optimize performance and add value to each project.

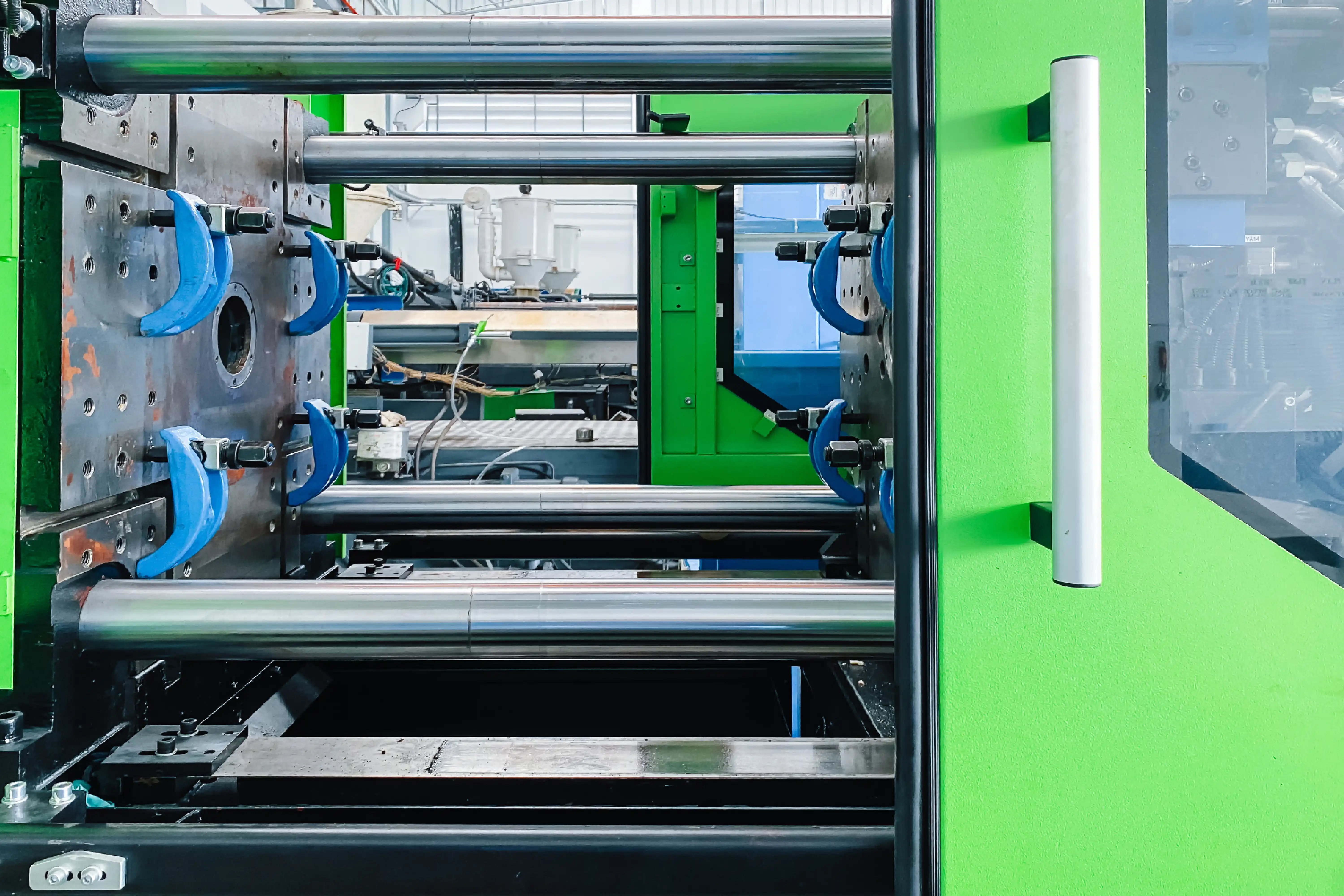

At Terzagen, we are dedicated to delivering innovative injection molding solutions that meet the evolving needs of our clients across various industries. With a commitment to quality, precision, and sustainability, we leverage our extensive expertise and advanced technology to provide customized manufacturing solutions. Our experienced team collaborates closely with clients to understand their unique requirements, ensuring that we deliver high-performance components that enhance their products and drive their success.

We excel in working with a broad spectrum of materials, including a variety of thermoplastics, thermosetting compounds, engineering plastics and engineering rubbers. Our extensive knowledge allows us to tailor our solutions to meet the specific demands of industries.

Our team employs advanced design and simulation tools to optimize mold designs and injection processes. By focusing on precision engineering, we achieve tight tolerances and superior surface finishes on every component. This commitment is essential in meeting the stringent quality standards.

Recognizing the importance of speed in product development, we offer rapid prototyping services that allow clients to quickly test and refine their designs. Our agile processes facilitate fast iterations, enabling you to accelerate your time-to-market while ensuring that your final product meets all specifications.

Our robust manufacturing capabilities are designed to support high-volume production without compromising quality. We utilize various types of injection molding machines, including hydraulic, electric, and hybrid systems, which enable us to optimize efficiency and meet diverse production needs.

At Terzagen, we are committed to sustainability and environmental responsibility. We implement eco-friendly practices throughout our injection molding processes, focusing on waste reduction and energy efficiency. Our goal is to provide high-quality products while minimizing our ecological footprint.

We understand that every project is unique, which is why we offer tailored solutions that cater to specific client needs. Our flexible approach allows us to adapt our processes and designs, ensuring that we deliver exactly what you need for your application, no matter how complex or specialized.

We prioritize excellence in forging, offering innovative solutions tailored to the diverse requirements of our clients across multiple industries. Our extensive forging capabilities integrate advanced technology, expert craftsmanship, and a strong emphasis on quality, enabling us to produce exceptional products.

Expertise in Forging TechniquesOpen Die Forging : Ideal for large components, this method provides flexibility in shaping metals through repeated hammering or pressing. It is particularly effective for creating custom parts where specific dimensions are required.

Closed Die Forging:This technique ensures tight tolerances and complex geometries, making it suitable for high-volume production. Closed die forging is perfect for components that require enhanced mechanical properties and surface finishes.

At Terzagen, we specialize in delivering cutting-edge heavy engineering solutions tailored to meet the diverse needs of our clients across various industries. Our expertise encompasses a broad range of services, ensuring that we provide comprehensive support for even the most complex projects. From large-scale machinery fabrication to structural components, our heavy engineering solutions are designed for durability, precision, and efficiency. Leveraging state-of-the-art technology and industry expertise, we are dedicated to delivering results that exceed client expectations and drive operational success.

At Terzagen, we pride ourselves on our advanced casting solutions, combining innovation with precision to serve a wide array of industries. We design our casting capabilities to deliver exceptional quality, performance, and customization, ensuring that we meet the diverse needs of our clients. With a focus on meticulous craftsmanship, Terzagen’s casting solutions guarantee reliable, high-quality components tailored to your specifications. Our commitment to innovation and adaptability enables us to support complex projects across industries, always meeting rigorous standards for excellence.

Our sand casting process is ideal for creating large and complex geometries. We utilize high-quality silica sand and advanced molding techniques to achieve exceptional dimensional accuracy. This method allows us to produce intricate designs with excellent surface finishes, making it suitable for both prototype and high-volume production runs.

For applications requiring intricate detail and tight tolerances, our investment casting process stands out. By using lost-wax techniques, we can create highly precise components with smooth finishes and minimal need for machining. This method is particularly advantageous for industries such as aerospace, medical, and automotive.

Leveraging advanced die casting techniques, we produce high-volume parts with consistent quality and efficiency. Our facility is equipped with state-of-the-art machinery capable of handling complex geometries in various materials, including aluminum and zinc alloys. This process is ideal for producing lightweight.